Woodcarver Ezine

Back Issues

Carvers' Companion Gateway

|

The bandsaw is not a tool that is used all the time in carving, but when needed, it can save considerable amounts of time by quickly removing large areas of unneeded wood. Depending on the carving and the size of the block of wood, sometimes it is better to just take a large gouge or fishtail and a mallet and just start removing wood. Other times it is better to use the band saw to remove pieces of wood to take the carving to a more visual, blocked shape of what the end results should be.

|

On the larger carvings (10 to 15 inches minimum) I usually use a table saw and a jointer to cut a block to size and then go from there with the knives. On smaller pieces, I will cut from 2 or more sides on the bandsaw to get the piece close to resembling the final product. For these smaller pieces, a bench top band saw was more than sufficient for the job. Considering the life of a bandsaw blade and the price of one, I try to use the bench top when ever possible; this avoids having to replace the more expensive blades of the full size (14 inch) bandsaw.

|

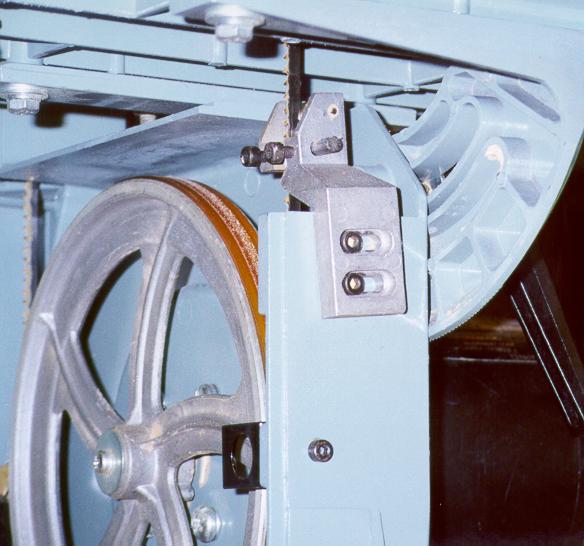

When selecting a bench top model, there are not too many choices to choose from. The Delta model was selected due to it being of the two-wheel design as opposed to the three-wheel designs, Delta's history of reliability and it was also the only one in stock at the time. The two-wheel design does force you to give up about 2 inches of width on the blade-to-arm distance however the extra amount of tension that is applied to the blades in the three-wheel designs will cause the blades to break much quicker. The price range for the bench top models is between $175.00 (US Currency) and $200.00 and the blades run around $7.00 a piece. The overall size/dimensions of the saw makes it a perfect size for the smaller shops such as the garage or basement that quite a few carvers seem to be setup in. Figures A & F show the front and inside views of the saw.

|

Specifications/Features:

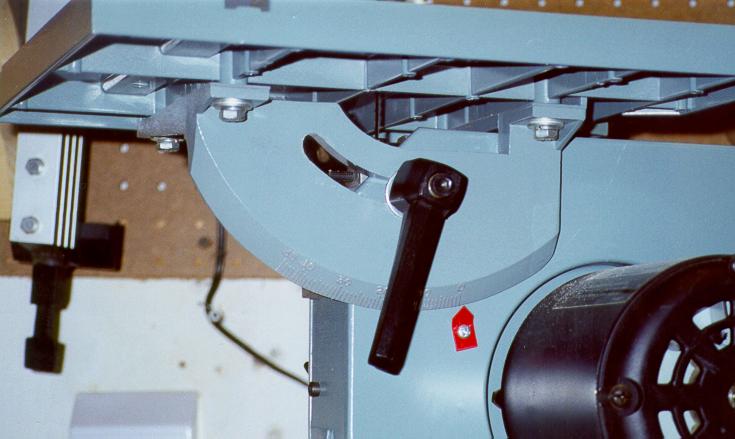

With this model, you get the full set of features that you would with the larger size models. The motor is a 1/5hp, 2.5amp, 115v, 60Hz, single phase motor. A toggle switch is used to power the saw; the switch also includes a removable key which locks the power off when not in use. The Table is 11 3/8 inches square (288.9mm) and will tilt up to 45 degrees to the right. Figure I shows the adjustment for the tilt. The distance from the blade to the frame is 7 1/2" (190.5mm) with up to 5 inches (127.0mm) under the guide. The overall size of the unit is 16 3/4" L x 12 1/4" W x 26 1/8" H (311.1 x 425.4 x 663.5 mm). The blades are 56 1/8" (1426.5mm) in length and turn at a rate of 3600 sf/m (1080 sm/m). The available blades for the unit are:

| Width | Min. Cut | TPI | Thick |

| 1/8" | 3/8" | 14 | .014" |

| 1/4" | 3/4" | 6 | .014" |

| 3/8" | 1" | 6 | .014" |

Other features of the saw include sealed (lubricated for life) ball bearing construction on both the upper and lower wheels, single-piece cast aluminum frame, hinged wheel cover, tracking control, and sliding blade guard for safety. There is also a port on the bottom of the back to allow for a vacuum hookup. With the use of the vacuum, very little dust will become airborne or remain inside the unit.

|

Blade Tensioning and Adjustment:

The design of this unit allowed for all blade adjustments to be quickly and easily accomplished. These adjustments should be checked whenever the saw is used. The design allows for a quick visual inspection that can be done at a glance; this includes the guide blocks, guide wheels and tracking. If any one of these is out of adjustment, it could result in a shorter life span of the blade as well as increase the likelihood of getting injured. To adjust the tracking, there is a knob on the back of the saw (in the middle of the top section) that is easily screwed in or out to adjust the tracking.

|

Figure G shows the backside of the unit where you can see the tracking knob in the middle of the top half of the unit. Also visible in Figure G is the blade tension adjustment knob. This is located on the very top of the unit and is also screwed in or out to adjust the tension; however this adjustment control is a lever which is flipped up 90 degrees to loosen the tension on the blade when not in use. Figure C shows the upper and lower blade guide units. Both units have independent adjustments for each guide rod and wheel; these are adjusted by using an allen wrench to loosen and tighten the set screw. The lower guides, visible in Figure E, can also be adjusted by tilting the entire guide unit forward or backward; set-screws are also used to hold it in place.

|

Maintenance:

Nothing more than general maintenance is required. Keeping the inside of the unit clean of excessive sawdust buildup and using a small compressor or vacuum to blow the dust out of the motor is all that is necessary to keep the unit running. The more dust trapped inside the unit will cause excessive heating of the blade and/or motor which will shorten the lifespan of the unit. With the wheel bearings being sealed, there is no oiling required for the life of the wheels. Occasional waxing of the top-side of the table will allow for the wood to gently slide over the table allowing for a smoother cut.

|

General Comments:

Overall, I was very impressed by the performance of this unit. The motor held up well to cutting a variety of woods from basswood to mahogany and from 1" to 4" in thickness. The 1/8" blade allow for some very tight and intricate cutting to be performed while the 3/8" blade allow for the cutting of the thicker woods and even some re-sawing to be done. Accurate re-sawing could be done on wood up to 2" thick, but beyond that the 3/8" blade was to narrow and flexible to provide a smooth, straight cut (even when manually angling the wood to follow the centers). When testing blades from different vendors, I found that I could get 15-20 hours of cutting from the Vermont American blades and 14-18 hours of cutting from the Delta blades. All others including the Sears blades provided around 12-14 hours of cutting. I found this saw to be very easy to setup and use, it takes up very little space, and provides a very smooth and controllable cut. For small projects I would recommend this saw to be used even over the larger floor models. It does save time on setup and maintenance and also saves on having to buy larger, more expensive blades.

Suppliers:

Woodcraft

210 Wood County Industrial Park

P.O. Box 1686

Parkersburg, WV 26102-1686

USA

1-800-225-1153

web site: http://www.woodcraft.com/Delta International Machinery Corp.

246 Alpha Drive

Pittsburgh, Pennsylvania USA 15238

1-800-438-2486WoodWorker's Supply, Inc.

1108 North Glenn Road

Casper, Wyoming USA 82601

1-800-645-9292