Back Issues

Carvers' Companion Gateway

A FISH STORY

David A. Steele, steeleadv@redrose.net

About a week before Christmas I got a telephone call from

a woodcarving friend who asked if I was interested in an unusual

carving project. He called because he knew that I would be. No

sooner were the words "Sure, why not?" out of my mouth,

I got a second call. This one was from a Mr. D.J. LaChappelle,

representing a group called SeaWeb.

"Your mission", said D.J., "should you choose to accept, is to carve a swordfish to represent a 266 pounder, and have it in New York City the morning of January 20th." Then there was silence. Racing through my mind were thoughts like, "What a great opportunity!", "I could make a lot of money!", "What great publicity for my work!", "Can I do it?", "What if I don't get it done?", "Will they pay me a lot of money?", and of course my answer was, "Sure, I'll do it. I'll figure out how later."

Six days 'til Christmas, seven more 'til the 1st, and 20 days until the press conference. Christmas Day off, the 28th is my birthday, the heck with that, New Year's Day off, a day for travel . . . that leaves 30 days for a 3 or 4 month project! Am I nuts? Of course, that's why my friend Jim called me in the first place. On the other hand, January is a slow month, and the exposure could only help. OK, I'll do it. Now, how much do I charge? No competition, because no one else would do it. Besides, they don't know anyone else. That means I should be able to get what I want. But if I ask for too much, I don't get anything. Let's see, 8 hours a day, five days a week, four weeks per month for three months times my normal hourly wage. All right, let's call D.J. in the morning. "That sounds fair enough to me. I'll call Vicki, the Executive Director, and run it by her."

28 days left. No call. 27 days left. It's Sunday. I can't reach D.J. Monday morning. D.J. says that Vicki hasn't called him about the project yet. She has a lot to do to get ready for the press conference and probably just hasn't had the time to call. He'll call her today. Tuesday morning. D.J. calls. "I'm sorry, Dave, but there isn't enough in the budget. We can only give you this amount, but when we're finished with it, you can keep the fish. Then maybe you can sell it for more. Standard negotiating. I have to act as though I'm not as interested in the project as I really am. I tell him that with the proper amount of time to complete the piece, I would probably be interested in such a proposal. As it is, however, I will have to drop everything and work on only this carving for the next 26 days, and can't afford to do that for that price. The only thing I could do for that price is purchase a fiberglass reproduction and paint it. "Hey, there's an idea! Let's try that!" D.J. is excited.

Feeling a slight surge of monentum, I go for the kill. "I will need a little more though, because I'd have the blank and shipping to pay for, since it'll probably come from Florida." D.J. will call Vicki.

Now I've got to find a blank. Where's my Breakthrough? I made some calls. The largest swordfish blank I could find is 110 inches long from tip of the bill to trail edge of the tail. It was made from a fish that weighed about 225 pounds. That's not 266, but who'll know? "OK, that'll do. When would I have it?" "Four to six weeks, plus a week to ship?" Even if I only took 3 days to prepare, paint and topcoat it, I'd need it in my shop in 3 and a half weeks. "NO WAY?" "Uh oh!" Call D.J.

Tuesday morning. "D,J., guess what! I found a fiberglass cast that would work, but even if I drove to Florida to pick it up, I wouldn't have it in time for the press conference . . . unless the press conference could be moved!" D.J. will call Vicki.

As I expected, the press conference could not be moved. At this point, fearing that the project was dead anyway, I decided to give it one last shot. I would carve the fish and deliver it to New York City by the 20th of January for just a little less than my original proposal. Cash. Up front. D.J. will call Vicki.

Wednesday, December 24th. "Here's the credit card number." 24 days left.

Where do I start? The most important thing is to get help. Fortunately, a carving friend who works in real estate was available. But not until Monday. Can't wait.

First we needed a pattern. The problem was that it was the day before Christmas and no one in the taxidermy or wood carving industries was stirring. No time to wait. We needed a working pattern for a fish that would weigh 266 pounds. My earlier research revealed that a 70 inch swordfish would weigh 25 pounds, a 95 incher would weigh 100 pounds and a 110 incher would weigh 225. Therefore, my calculator told me that a 266 pounder would be 123 inches long. OK, we're rolling. Now, what does he look like? Searching through my personal library, I found a taxidermy painting book that had a photo of a swordfish reproduction, along with a painting schedule. The only problem was that it was of a small fish, about four feet long. Since there was not enough time to properly research this project, I had to work with what I had on hand, let my experience take over, and hope for the best.

Knowing that a fish doesn't grow proportionately as it matures, I re-drew the pattern, adding girth to the belly, heighth to the head, and a little size to the fins, but keeping the ratio of major body parts the same. After a couple of modifications and re-draws, I had a 14 1/2" pattern I liked. Now to enlarge it to 123 inches! A sign company! Great idea! They make huge patterns from small ones all the time! I know it's the day before Christmas, but I'm working. I'll call. No answer box. They're open! "Could I bring a 14 1/2" paper pattern to you and have it enlarged by 848%?" "Monday? That's five days from now! Thank you, but I don't have five days to waste." Fortunately, there was a video store with a copy machine within walking distance of my shop. Time to put "Plan B" into effect. It meant a lot more work, but it surely beat waiting five days to continue.

The day after Christmas, when everyone else was exchanging merchandise and

buying leftover cards and wrapping paper, I was in the shop piece-mealing

a full-size swordfish pattern. Greg at the video store and I

became good friends over the next couple of days. The pattern

had to be enlarged in steps, since the copier could only enlarge

by 200% at a time. The first step gave me a pattern that was

29 inches long, with thick pencil lines. I was afraid the thickness

of the lines would throw off the finished pattern, so I re-drew

them at the new size, and twice more before I was finished. I

also laid out a grid of 2" squares over the pattern and

numbered the squares, so I'd always know which piece of the "puzzle"

went where. The next enlargement gave me 4" squares, the

next 8", and the final step gave me 8 1/4" squares.

Now I had 42 sheets of 8 1/2" x 11" paper, which when

re-assembled, gave me my full-size pattern. I then cleared a

10' x 4' section of wall, drew some center lines, and taped together

the sheets. Now how was this to become a woodcarving?

The day after Christmas, when everyone else was exchanging merchandise and

buying leftover cards and wrapping paper, I was in the shop piece-mealing

a full-size swordfish pattern. Greg at the video store and I

became good friends over the next couple of days. The pattern

had to be enlarged in steps, since the copier could only enlarge

by 200% at a time. The first step gave me a pattern that was

29 inches long, with thick pencil lines. I was afraid the thickness

of the lines would throw off the finished pattern, so I re-drew

them at the new size, and twice more before I was finished. I

also laid out a grid of 2" squares over the pattern and

numbered the squares, so I'd always know which piece of the "puzzle"

went where. The next enlargement gave me 4" squares, the

next 8", and the final step gave me 8 1/4" squares.

Now I had 42 sheets of 8 1/2" x 11" paper, which when

re-assembled, gave me my full-size pattern. I then cleared a

10' x 4' section of wall, drew some center lines, and taped together

the sheets. Now how was this to become a woodcarving?

It was obvious that this "fish" needed to be made in pieces. The fins, tail and bill were convenient places to make joints. The rest wouldn't be so easy. The taxidermy supplier in Florida gave me a lot of critical information about the swordfish that I couldn't have done without. I've always told students that woodcarvers need to have at least two friends -- a dentist for discarded tools and a taxidermist for reference materials. The real fish, I learned, would be about 12" thick at the thickest point, the rear edge of the gill cover. Since this piece was being made as a wall mount, that meant that I needed 6 inches of thickness to the centerline of the fish's body where the fins, tail and bill were attached, and about 3" more to the wall, so that the piece could be rounded to give the appearance of a full body. It was decided to make the body portion hollow to save on both wood and weight.

The bill seemed a likely place to start, so I traced a bill pattern from the overall pattern on the wall, selected a 1" thick piece of basswood, and got started. By the time the carving was completed, we had used just about every piece of wood, clamp, bottle of glue, and tool in the shop.

Monday morning, December 29, 20 days left. Help arrived in the person of Sean Casey, close friend and fellow carver with a similar fondness for the uncommon. Sean's unique ability to make any task enjoyable, along with his dedication and hard work would prove to be invaluable. Bandsaws, Foredoms, angle grinders, mallets and chisels, drills and palm sanders were constantly in use as the fish began to take shape, piece by piece.

Wednesday morning, December 31. First speed bump. I arrived first, about 7 a.m., feeling sick as a dog with the flu. By 11:00 I felt worse and went home. Sean continued working throughout the day and the next to make up for my absence.

The head and body sections of the fish were designed to be hollow. Since they both needed to be 9" thick at the thickest part, the wood had to be stacked and laminated. This required an outside service, since I don't own any planing equipment. This was a potential time loss, but thanks to another carver friend who lent us the use of his equipment, it went smoother than expected.

Monday, January 5. 14 days left. Second speed bump. The eyes did not arrive as expected. I was already on the phone as the UPS truck sped past without stopping. They had just been shipped that morning and I could expect them by Friday. By Friday the fish was in one piece, waiting for an eye. My excitement turned to horror as we opened the package and found red eyes instead of blue ones. Another, even more frantic call to the supplier. Blue marlin eyes, very similar to what we needed, just happened to be on the shelf and would be shipped out that day via overnight delivery so that we would have them on Monday. Not having time to wait for the new ones, we drilled the head using the red eye for size and continued. We detailed the fish, cleaned up all the joints and applied four coats of gesso, sanding between each.

Monday, January 12, 7 days left. As promised, blue eyes arrived by 11:00 a.m. By 11:30, one was in the fish and the other was hanging on the wall. (If anyone needs one 82 mm blue marlin/swordfish eye, please call, because I don't expect to be carving another one.)

Now the fish is ready to paint. Schedule is holding well. The first two coats are white enamel. These smooth over any small imperfections and provide a good surface for the next coat to adhere to. Next is the first basecoat. For the highest degree of reflectivity, I've chosen Duplicolor Chrome Enamel. The entire fish is coated, and it looks fantastic. It looks like a brand new chrome bumper! Now the shiny silver color should show through the semi-transparent acrylic airbrush paint for a perfect look. We'll see in the morning when it's dry.

Tuesday morning, January 13, 6 days left. Not too early, about 9 a.m. The chrome paint is not dry. Now what? We'll check it again at noon. Still tacky. Can't wait, but can't paint over a tacky coat either. Steel wool! That's it! If we steel wool it lightly, we'll expose the tacky paint just under the surface and allow it to dry more quickly. I must have applied the second coat of chrome too soon and too heavily. I was so excited because it looked so great! Steel wool seems to be working. We'll check it again at 3:00. Got to be painting by then. Now the chrome look is gone. It looks more like pewter, but it still looks good. 3:00 and it is just a little tacky. Can't wait. Let's paint! Sean has never airbrushed, so he was happy to mix paint, clean airbrushes, watch and learn. I was more than happy for the help. For painting reference, I used the Breakthrough Fish Painting Encyclopedia, photos I found in two saltwater gamefish identification manuals, a photo sent by another carver friend in Delaware, and info from the Billfish Foundation I pulled off the web. I painted until about 11:00, leaving the details for the next day.

Wednesday, January 14, 5 days left. Painting went rather smoothly. I stopped only when Sean cut off my air supply (to the airbrush, that is). I was unaccustomed to finishing early, so I was nit-picking.

Friday morning, January 16, 3 days left. Experience told me that by now the acrylic airbrush paint was cured enough to topcoat. We loaded the fish into my minivan and delivered it to the sign company for the clear coat. Terry, the owner, had clear coated fiberglass fish reproductions with the same two-part automotive polyeurethane he planned to use on our carving, so I wasn't worried. . . until he called Friday night to ask us to come and take a look. Apparently the chrome paint still wasn't fully cured, because it reacted with the clear coat and wrinkled the acrylic paint. Terry said that the guys in the shop liked the finish it created, saying it looked more like a fish skin. He was going to wait until Saturday morning when the clear coat was fully cured, wet sand the entire fish and apply another coat so that the surface would be smooth. There were also three quarter-sized areas where the clear coat blistered and didn't stick at all. We decided to carefully cut around the blisters, remove them and recoat.

Saturday, January 17, 2 days left. We went to pick up the fish about 5:30 p.m. The finish was smooth and deep. The paint actually did look more like a very slightly orange-peeled skin than it did earlier. The three quarter-sized blisters did not turn out as well as expected, however.

Sunday, January 18, 1 day left. I was in the shop repairing the blistered spots. By the time I finished, no one could tell where they were, except for me.

One more task to complete before delivery. Since this fish could not hang on the solid cherry panelled walls of Felidia, the restuarant in New York City where the press conference is to be held, we had to come up with another idea. A simple, sturdy, knock-down weight-bearing display stand is what we needed, and fast. Wood is the natural choice of materials, but we couldn't make it sturdy enough without being large and obtrusive-looking. PVC pipe is a possibility, but isn't sturdy enough. How about steel pipe? A quick trip to Hechinger's for 1 1/2" steel galvanized pipe, elbows, T's, collars, end caps and floor flanges, and we've got a display stand. Back to the shop for assembly and a test hanging. Perfect! Now to make it look good. Wash it down with acetone to get rid of the grease from manufacturing and sand it to rough up the surface so that the paint will stick better. Two coats of white RustMaster Enamel Primer and two gloss coats later, and we're finished! And there's half a day left!

Monday, January 19, Delivery Day. Boy am I glad I bought the Grand Caravan with the extra length! By removing the two rear seats and positioning the fish with its bill and head between the front seats, we had about an inch to spare both front and back for the three hour ride to New York.

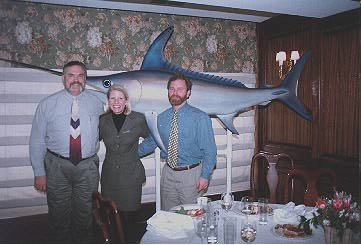

Tuesday, January 20, Press Conference Day. By 12:00 noon Billy the broad-billed swordfish greeted a packed house of photographers, writers and camera crews from the nations's media, and two woodcarvers from Pennsylvania couldn't be any prouder.

Wild About Wildlife,

David A. Steele