There are many revelations by artists about what inspires them or where inspiration can be found. Some of those revelations are inspirations in themselves. Whether it is a writing, a painting, a photo, or, especially a carving, the more I enjoy the piece, the more I want to know what launched the artist into that particular creation. If you practice this enough, it sometimes results in you finding similar inspiration, but with very unique and personal results. The inspiration for this electric violin was simple. It was the combination of a short tradition carving graduation gifts for my daughters and cowardice. That's right the main ingredient was pure fear. At this point if you're not in the mood for lengthy explanations, it is your chance to exit. Still with me? OK, you were warned.

Some history: A year before her high school graduation, I had the bright idea to carve my younger daughter, Melissa, a violin as a graduation gift. The project started well. There are several books on the subject "out there", some fairly plentiful information on the web, places nearby where tone woods could be purchased, and several mail order sources for tools. You can find preformed tuning pegs, tailpieces, fingerboards, and chinrests for sale. There are even kits available in various stages of completion. So, graduation time was getting closer, and there were two books on the bookshelf, all the maple and spruce that was needed, and a bag full of rosewood tuning pegs, tailpiece, and chinrest. The two pieces of maple were glued up for the back, and that's as far as it went. Is there such a thing as woodcarver's block? Believe it! I can sometimes sneak up on a project that's a little beyond me, but not this time. Melissa is a big collector of turtle "stuff", so she actually received a sea turtle carving for her high school graduation, and a promise of a violin for college graduation. She didn't seem disappointed, but you could tell she was going to hold me to the promised of a violin.

Thinking I had four years to wrestle with the violin project I breathed a little easier. That was a mistake. It seems that midway to a B.S. in Nursing, Melissa graduates with an Associates, and she wants to know how the violin is coming. Add to that pressure a second carving project for my older daughter, Laura, who is graduating at the same time with her B.S. in Elementary Education. See? Fear and desperation can bring on great inspiration. So, why did I see an electric violin as my salvation? 1) Solid body electric violins are expected to sound a bit different from acoustic violins. 2) I trusted electronics for amplification more than I trusted my carving ability to produce the violin body that is required for acoustic amplification. 3) Removing the acoustic amplifier left a lot of room for creativity where the traditional violin body should have been.

As near as can be

recalled, this is how the design came about. First question: What

do you absolutely have to preserve from the acoustic violin design

so that the electric version doesn't require re-learning a new

instrument. Starting at the bottom there is an anchor point for

the tailpiece, a place for the cheek rest, a place for the bridge

to sit against, the fingerboard, and the shape of the violin neck

should be retained. OK, so these can be all mounted to a stick,

with a wing for the cheek rest. Well, that's pretty ugly but a

start. Let's overlay an outline of a traditional violin over that

and draw a nice curved "S" within the shape. Not bad.

There's a place for the cheek rest, but the "S" is too

recognizable. It would be fine if our name was Stevens or Smith.

So, reverse it then. That's better. With "the stick"

it's slightly like a G-clef. Make it a G-clef? No, too cliché.

Hmmmm, the reverse "S' has a nice shape, a nice flow. Flow/water

. . . water/turtle . . . turtle/uniquely Melissa's violin.

As near as can be

recalled, this is how the design came about. First question: What

do you absolutely have to preserve from the acoustic violin design

so that the electric version doesn't require re-learning a new

instrument. Starting at the bottom there is an anchor point for

the tailpiece, a place for the cheek rest, a place for the bridge

to sit against, the fingerboard, and the shape of the violin neck

should be retained. OK, so these can be all mounted to a stick,

with a wing for the cheek rest. Well, that's pretty ugly but a

start. Let's overlay an outline of a traditional violin over that

and draw a nice curved "S" within the shape. Not bad.

There's a place for the cheek rest, but the "S" is too

recognizable. It would be fine if our name was Stevens or Smith.

So, reverse it then. That's better. With "the stick"

it's slightly like a G-clef. Make it a G-clef? No, too cliché.

Hmmmm, the reverse "S' has a nice shape, a nice flow. Flow/water

. . . water/turtle . . . turtle/uniquely Melissa's violin.

How else can I make this uniquely Melissa's

violin? Well she also loves swimming on her college's swim team.

The turtle goes there . . . make it a sea turtle because they

"fly". . . the swimmer goes here . . . hmm, third turn

needs something. How about a dolphin? It fits. Now something isn't

quite right about the flow of water criss-crossing "the stick".

Well then pick a direction of flow for the water. It originates

from a spring just above the turtle, crosses the stick, under

the cheek rest, the swimmer is on it's crest, back across the

stick at the bridge, turns with the dolphin, back across the stick,

then "spills" into space. Make the stick part of the

design every time the water crosses it, it crashes off the stick

a little on the "upstream" side, and becomes the source

of the flow on the other. OK, instead of the traditional scroll

above the fingerboard we'll do another surf-wave crashing onto

the peg box. That will tie it together well.

Hey! Don't forget

to hollow out the back of the stick for electronics. Where does

the phone jack go? Here, so the cable can go back behind her.

Volume control? Here, but make the knob from wood same as the

body, so it doesn't attract attention. By now you understand that

the design process turns into this intimate conversation with

myself. Hopefully that's not a unique process and doesn't require

therapy. This method usually works well for me except when the

conversation gets heated. Then I get ticked off with myself, stop

speaking, and the creative process comes to a screeching halt.

The one big advantage is, in the end, I'm always right . . . are

not. . . .am too . . .are not! Well fine then!

Hey! Don't forget

to hollow out the back of the stick for electronics. Where does

the phone jack go? Here, so the cable can go back behind her.

Volume control? Here, but make the knob from wood same as the

body, so it doesn't attract attention. By now you understand that

the design process turns into this intimate conversation with

myself. Hopefully that's not a unique process and doesn't require

therapy. This method usually works well for me except when the

conversation gets heated. Then I get ticked off with myself, stop

speaking, and the creative process comes to a screeching halt.

The one big advantage is, in the end, I'm always right . . . are

not. . . .am too . . .are not! Well fine then!

Walnut was my first

choice for the project and a good friend and carving buddy of

mine donated a piece he had stockpiled. It was a thick, gorgeous

piece of wood and, if I cut carefully, the body and neck could

be all one piece with enough waste left to form the back to the

hollowed out electronics area. A problem with the walnut was that

it didn't go well with the preformed rosewood pieces I already

had. This was solved by using the parts as models and carving

my own set of tuning pegs, tail piece, and cheek rest from a block

of English elm I had stashed away. The pre-shaped ebony fingerboard

looked fine and added a third shade of wood. Yes, most of the

decision to use the "store bought" fingerboard was also

cowardice. Ebony is supposed be right under diamonds on the hardness

scale. Early stages of shaping the body utilized my 14" Rockwell

wood/metal band saw and the drill press fitted with Forstner bits.

The Forstner bits were great for hollowing out the tuning peg

box, the electronics area under the bridge, and the areas inside

the curve where the band saw would have required an entry cut.

After that it was 95% hand tools, scrapers, riffler files and

my shop stereo. Stringing or setting up the violin was aided by

the loan of a "real" violin by a friend of Melissa.

Walnut was my first

choice for the project and a good friend and carving buddy of

mine donated a piece he had stockpiled. It was a thick, gorgeous

piece of wood and, if I cut carefully, the body and neck could

be all one piece with enough waste left to form the back to the

hollowed out electronics area. A problem with the walnut was that

it didn't go well with the preformed rosewood pieces I already

had. This was solved by using the parts as models and carving

my own set of tuning pegs, tail piece, and cheek rest from a block

of English elm I had stashed away. The pre-shaped ebony fingerboard

looked fine and added a third shade of wood. Yes, most of the

decision to use the "store bought" fingerboard was also

cowardice. Ebony is supposed be right under diamonds on the hardness

scale. Early stages of shaping the body utilized my 14" Rockwell

wood/metal band saw and the drill press fitted with Forstner bits.

The Forstner bits were great for hollowing out the tuning peg

box, the electronics area under the bridge, and the areas inside

the curve where the band saw would have required an entry cut.

After that it was 95% hand tools, scrapers, riffler files and

my shop stereo. Stringing or setting up the violin was aided by

the loan of a "real" violin by a friend of Melissa.

Parallel to the carving

process was research and construction of the electronics. Research

was done entirely on "The Web". Several sources advised

piezoelectric pickups over the coil pickups used on electric guitars.

Piezoelectric wafers basically change electrical energy into mechanical

energy (piezoelectric buzzers) or mechanical energy (string vibration)

into electrical energy (an electric signal). Several three dollar

piezoelectric buzzers from RadioShack were sacrificed and dissected

for Melissa's electric violin. After that, more research turned

up a circuit that would match the impedance of the piezoelectric

element to that of an electric guitar pickup. This meant the violin

could be used with an electric guitar amp sometime in the future.

The circuit also amplified the signal enough to drive headphones.

Now, I have a very poor track record with electronic projects

requiring soldering skills, because I have none. More Web research

rescued me again with a very basic tutorial on the do's and don'ts

of soldering circuit board projects. Even with global support,

it took three prototypes before I had a working amplifier. This

was then transplanted into the violin the day before Melissa's

graduation. The circuit required two 9 volt batteries instead

of one, so the back required some last minute hollowing out. I

thrive on pressure.

Parallel to the carving

process was research and construction of the electronics. Research

was done entirely on "The Web". Several sources advised

piezoelectric pickups over the coil pickups used on electric guitars.

Piezoelectric wafers basically change electrical energy into mechanical

energy (piezoelectric buzzers) or mechanical energy (string vibration)

into electrical energy (an electric signal). Several three dollar

piezoelectric buzzers from RadioShack were sacrificed and dissected

for Melissa's electric violin. After that, more research turned

up a circuit that would match the impedance of the piezoelectric

element to that of an electric guitar pickup. This meant the violin

could be used with an electric guitar amp sometime in the future.

The circuit also amplified the signal enough to drive headphones.

Now, I have a very poor track record with electronic projects

requiring soldering skills, because I have none. More Web research

rescued me again with a very basic tutorial on the do's and don'ts

of soldering circuit board projects. Even with global support,

it took three prototypes before I had a working amplifier. This

was then transplanted into the violin the day before Melissa's

graduation. The circuit required two 9 volt batteries instead

of one, so the back required some last minute hollowing out. I

thrive on pressure.

Happy ending: The graduations went well, and both daughters were pleased with their carvings. What was Laura's project/gift? It was a faery with pierce carved wings, which is a companion piece for the unicorn I carved for her high school graduation. A story for another time. . . .

More progress and finished photos HERE.

Mike

Bloomquist is a carver and carving teacher, and a frequent contributor

to WOM.

Mike

Bloomquist is a carver and carving teacher, and a frequent contributor

to WOM.

You may visit Mike's web site, Wooden Dreams Woodcarving at http://www.borg.com/~bloomqum/index.htm or email him at m.bloomquistATverizonDOTnet.

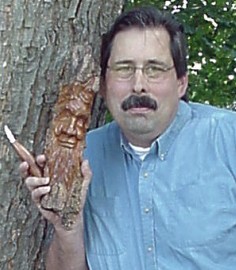

<-Mike Bloomquist- and Friend (Mike is on the right!)